At the end of November I was part of the privileged group of interior design colleagues that were treated to an incredibly insightful ‘Discovery Day’ at the Porta Romana Headquarters in Farnham, Surrey.

I have worked with Porta Romana throughout the course of my career. Specifying their beautifully handmade lamps and furniture for discerning clientele throughout the UK and abroad. So, when this exciting invitation came about, I naturally said yes straight away!

I am always impressed with the high level of design, craftmanship and customer service Porta Romana delivers. Seeing how all of this is orchestrated at the Discovery Day, together with how the company has evolved over the past 30 years, has reaffirmed my love for this wonderful brand.

Before I get into the details of the day – here’s a little history of Porta Romana…

“Porta Romana began life in 1988 in a tiny London workshop. From the beginning, the ambition was to create beautiful and inspiring pieces that would be loved. Good fortune came in finding skilled British craftspeople to create those quirky and original designs.

The Porta Romana style and design language has continuously evolved over the following quarter century to become a leading global brand, and a critical ingredient in the world’s most beautiful houses, yachts, hotels and movie sets. Porta Romana still works with some of their original artisans, and now continue to seek out new artistic talent, to help breathe fresh life into their collections.”

The Discovery Day Experience

Product Design Team

We first met with Spencer Marsh, the Senior Product Developer at Porta Romana. Spencer took us through the very initial processes for each design that is created. We took the Urchin Chandelier as an example.

The Urchin Chandelier was modelled on a chestnut seed pod, first found by the founder’s dog whilst out on a walk! The design was carefully developed from a simple conceptual sketch to a highly technical 3D model using specialist product computer animated software. Prototypes are then made with their Makers to ensure the design works harmoniously.

The Urchin is forged in metal. Each piece of the Urchin is carefully assembled to make sure the fit is perfect before it is then taken apart and sent to the Paint Studio to have the specialist hand painted finish applied. These options include Bodu Gold, Bodu Silver or Flint White – each finish looks stunning, although my favourite is the Bodu Silver – I love how the paint works with the underlying metalwork.

Spencer also explained to us how Porta Romana’s vast product library of ideas, going back decades, is often referred to in order to aid the design process. What a wonderful resource to have! We were also fortunate enough to see a 3D printer making a model for a future design. Quite incredible how technology has rapidly evolved in the recent years, allowing us to use tools that until recently didn’t even exist.

The Design Studio is led by Shazeen Emambux, Porta Romana’s Creative Director. Shazeen was pretty busy during our tour; but she works closely with the product design team throughout their design process. Constantly collaborating with their craftspeople and paint studio to bring all their innovative creations to life.

Figure 5 Trevose Mirror made in cast composite finished in French Brass

Figure 5 Trevose Mirror made in cast composite finished in French Brass Paint Studio

Porta Romana call this area ‘the workshop’ – it really does feel like the heart of the company, and where the magic happens! This is where you will find dozens of skilled artists carefully transform the metal, wood and composite substrates into exquisite pieces of art and sculpture. The Paint Studio team use carefully curated processes that are the same today as the when they were first fashioned several decades ago.

Figure 6 Artists at work

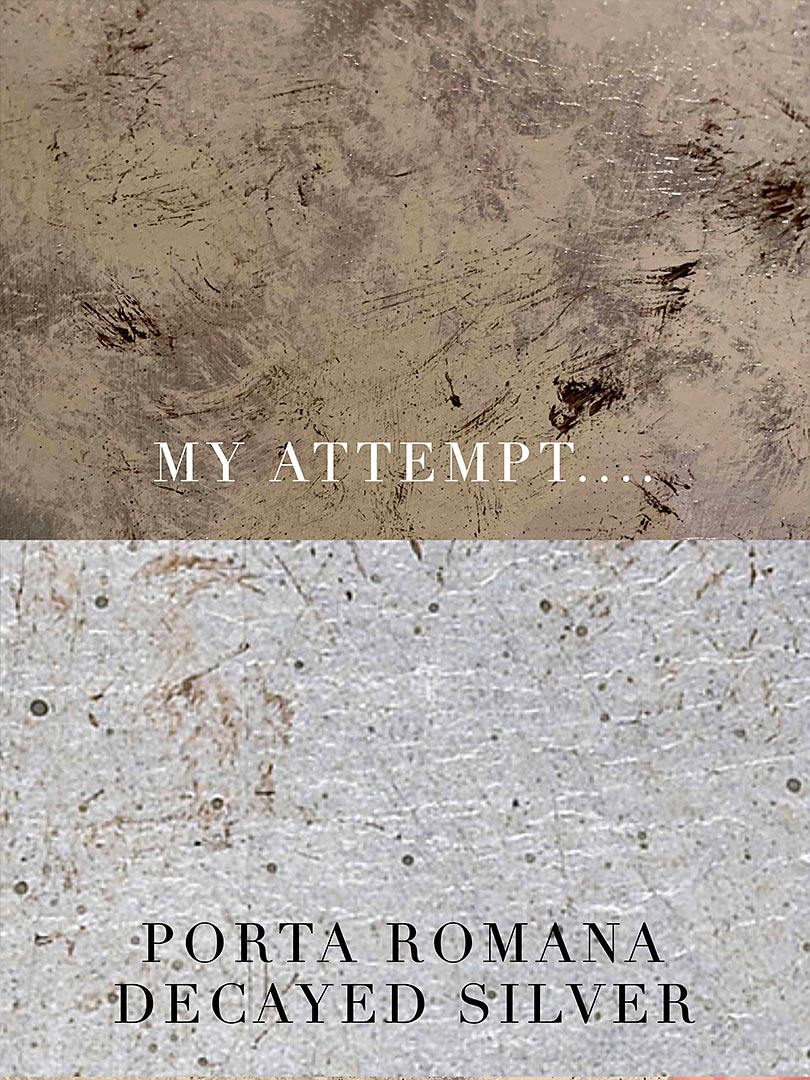

Figure 6 Artists at work A Porta Romana artist, Vikki Joint, gave us our very own lesson on how to achieve the famous decayed silver finish – credit to Vikki’s teaching skills and patience! Aproned up and with our white gloves on, we got to work creating our own sample cards. I would call these a working progress, of course I can only speak for myself!

After our own private lesson in making the decayed silver finish, Vikki took us to each design table in the Paint Studio and explained all the processes taking place. Probably my favourite moment was watching a Steel Plates Wall Light being finished in Mayan Gold. I was stunned to learn that this finish takes three pain-staking days to achieve! Layers of gold leaf and texturing paints are applied – in total 15 different processes using 16 diverse paint brushes to create this incredibly precise finish.

Stores Department

At the Stores department each product received in from each of Porta Romana’s Makers is thoroughly checked by Stores Supervisor Ben Cook and his team. Perhaps there may be a small air bubble in a glass lamp, or a fitting may not be attached correctly – all issues are flagged up before being sent back to the Makers for re-finishing or decommissioning. Each item has its own document outlining the issues making it very clear to the Maker where to re-invest their efforts. It was evident from our experience that the quality control on each and every item that is made by Porta Romana had to meet exacting criteria before being processed onto the Production Manager. Ben then carefully categorises each item. For example, table lamps more often than not are bought in pairs. It is therefore correctly assumed that the lamps should look as identical as possible (we learned out later how extremely challenging this is!). Therefore, Ben would prudently check each lamp design to pair it with a partnering lamp. These lamps are then bagged up and stored together for their future owner. Who would have known such attention to detail, even at this stage, would be required to ensure Porta Romana’s reputation? I certainly didn’t – but I now understand how important each of these processes is to leave us with the end product in our homes.

Assembly Department

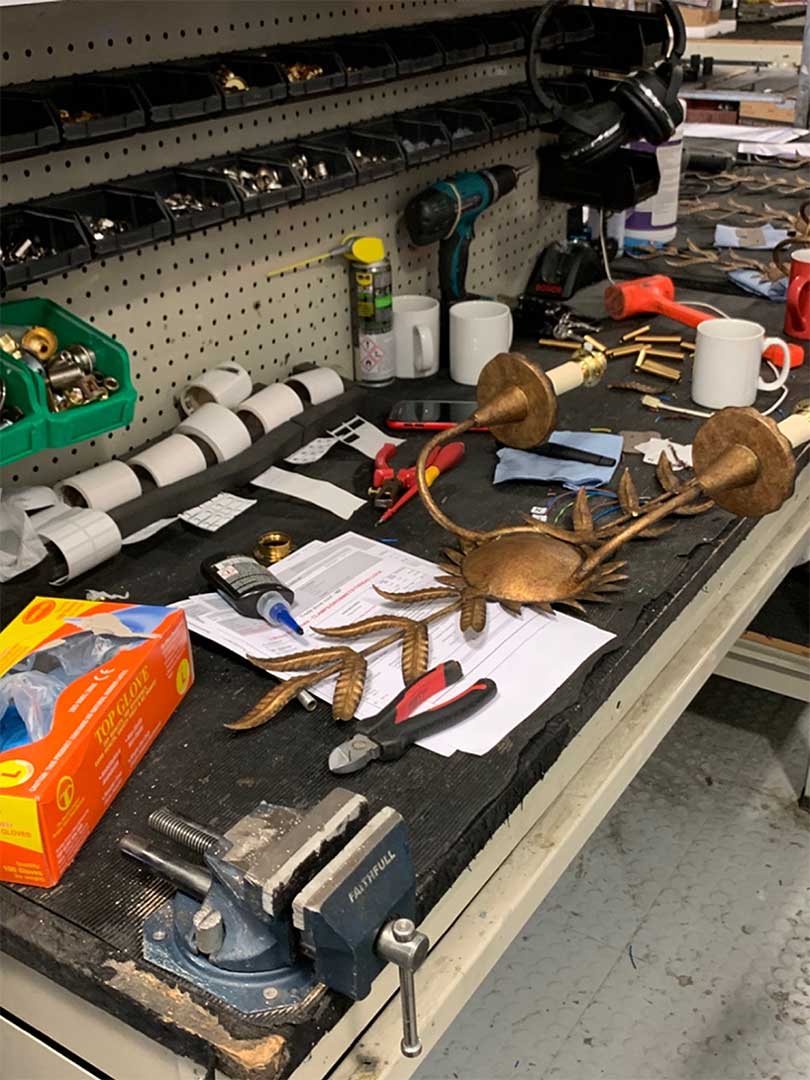

We were then met with Production Manager Richard McConnel who walked us through to the Assembly Department. This is where every product is wired and tested – not just for the UK, but for any country the product is destined too. I loved seeing all the different coloured flex available.

Despatch

Anyone who has received a Porta Romana package will understand the enormous amount of consideration that has gone into how each product has been packaged. Lamps and furniture often have to travel across countries, and even continents, to get to their final destination. Therefore, it is quite rightly very important that their packaging is carefully considered.

Lamps and shades (and even the flex and sockets!) are covered in their own dust-bags before being carefully placed inside their respective boxes. A specialist solution is then interested into a bag – this solution reacts with the air; gradually expanding and hardening around the contents of the box. Assembly instructions are also given their own cardboard pouch to avoid them getting lost during de-packaging. All product keep at their warehouse is stored in climate controlled warehouses to ensure the materials are kept safe from cracking.

Lunch

After that whirlwind of a morning we were very ready for lunch. Hosted by Jackie (Sales Director), Olivia (UK & International Sales Manager) and Leah (Our Account Manager). Discussing all that we had learnt from the mornings tour and gaining more of an insight into how the company operates. What was clearly demonstrated was the core values of the company – a very friendly, close-knit and positive attitude, where it seems for everyone the main goal of each person I met was to create beautiful designs made to the highest standards. It was easy to get side-tracked, for example during our lunch we spotted some Dumpling lamps. Each lamp was in the same base, snow, with putty silk shade – the difference was each lamp had a different lining. It was incredible to see how the lining makes such a difference with each lamp, see image below. Finally, we were introduced to Managing Director, Ali Milam. It was very clear from our brief introduction how this global brand had evolved from very humble and sincere beginnings.

Custom & Bespoke

Subsequently after lunch, and our digressing, time was not on our side by this point! Fortunately, we had the walking encyclopaedia that is product manager Zoe Burke talk us through the constellation of customisable options available to us as designers.

I had always thought I had a good grasp on what was available, I stand corrected! From flex colours, lengths to switch positions, even to the type of metal used on the light fittings is interchangeable. This last point I can’t stress enough how pleased I was to learn! When as a designer you design for example a bedroom using perhaps an antique brass for metalwork – to know we can still use any choice of lamp at Porta Romana and simply ask to use antique brass for the metal base is a revelation! No more hours spent searching for lamps with particular metal requirements.

Zoe also talked us through how every product is customisable, from console table to ceiling light fitting. We also learned how and why costs are associated with each element. This information will prove extremely helpful in explaining to prospective clients exactly how their finances are being correctly invested.

Finally, Zoe explained how Porta Romana strive to achieve the perfect shade. All Porta Romana’s shades are made up using wirework that is 4mm thick and powder coated in their signature champagne colour. Normally standard shades are used using 3mm thick wirework. This means that the extra rigidity provided by the Porta Romana shade gives it much more durability – giving further longevity to the shade’s lifetime.

Glassblower

The final part of our tour took us half an hour’s drive away to the specialist glass blower workshop of Adam Aaronson.

Whilst at the workshop we sat in front of the glowing furnaces, captivated as Adam and his colleague made one of my favourite Porta Romana lamps – The Avocado. In fact I have two Avocado Lamps in my home, suffice to say I was especially grateful for this incredible experience! Each glass lamp is blown and gradually made larger before being stamped with an ‘S’ iron – the glassmaker then manipulates the glass by twisting and turning it. Cooling it down, rubbing it with newspaper before repeating the process over and over until the famous Avocado shape appears! It was mesmerising to watch. Now, going back to what I said earlier in this blog where Ben Cook has to pair each lamp – when you see how these lamps are made it seems like a miracle they are even vaguely similar – let alone matching!

We also got to watch the Adam Lamp being made, where each glass ‘pebble’ is carefully blown to achieve this stunning design.

Figure 22 Freshly made pebble…

Figure 22 Freshly made pebble… Finally – our last treat was to watch how the Thread Lamp is made. Where glass is carefully spun around the glass vase centre. In a way not too dissimilar from watching candy floss made! Just with 1000+ degrees Celsius and with immense skill.

What was striking about this part of our tour was that Adam explained most lamp makers use glass vases and create the metal fixings to fit the vase – thus turning it into a lamp. However, all of Porta Romana’s lamps have been carefully designed to fit their standard metal fixings, without a millimetre to spare. This is achieved with careful precision by the glass maker and then carefully polished down by the in-house glass polishers using specialist machinery.

After a very full Discovery Day at Porta Romana I felt very grateful to have had such an in-depth insight into the workings of this charming brand – a slick operation to say the least and an experience I would highly recommend to any designer seeking to understand more about their supplier’s processes. A big thank you to all at PR HQ!

Figure 23 Congratulations on 30 years!

Figure 23 Congratulations on 30 years!

22nd September, 2025

14th March, 2025